How the right printer can help improve food traceability

Food and groceries represent the second-most common type of product recall in Australia after cars, according to the Australian Competition & Consumer Commission.

Every consumer should be able to trust in the food products they and their families consume. However, it’s inevitable that mistakes will happen at times, and food or beverages will need to be recalled for the safety and health of consumers.

Recalls aren’t simple processes, though. When a food product is contaminated or otherwise unsafe to consume, the company issuing the recall must find out:

- How the product became contaminated

- Where it came from

- Where it was distributed

- How to disperse recall information

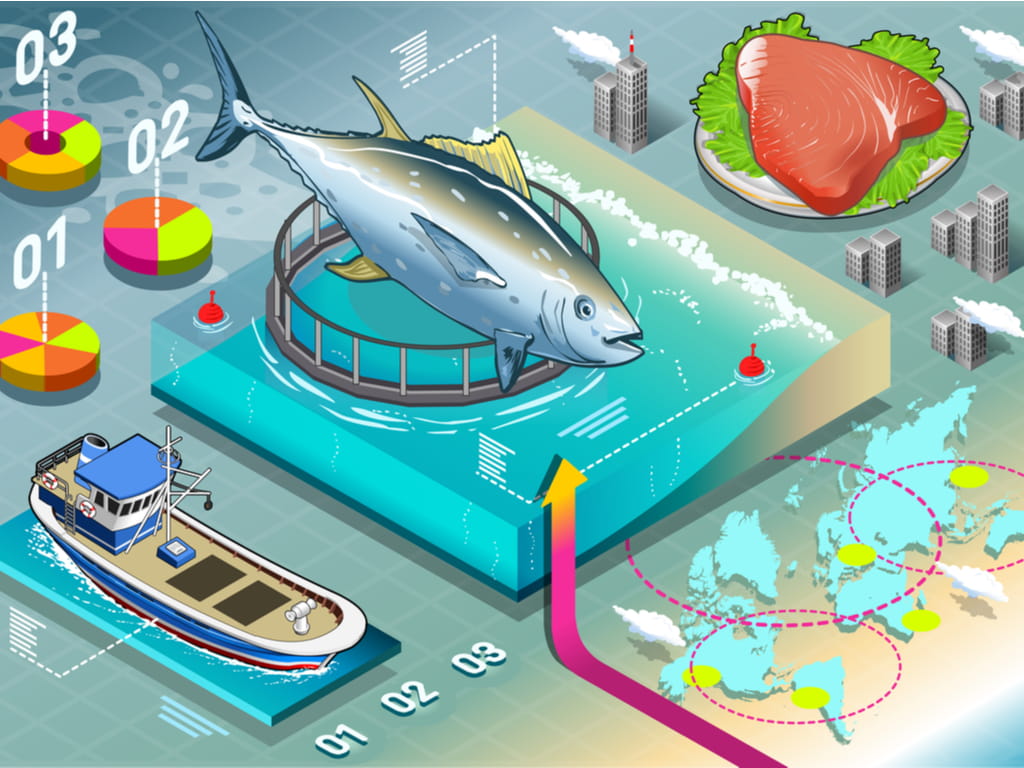

To make matters even more complicated, each food item typically goes through multiple steps in the supply chain before becoming the end product consumers purchase at the supermarket. Each of those individual organisations will have varying methods of recording product information, making it difficult for any one company to access all the information about where specific foods have been.

The best way to ensure consumers and companies have the information they need about food products is to strive for accurate traceability at every stage of the supply chain.

Food traceability standards in Australia

Australia is a global leader in food safety, and was an early adopter of strong traceability systems and standards, according to the Australian Trade and Investment Commission.

With a comprehensive traceability system, the previous and next steps for any single food product can be known at any point in the supply chain. This applies to raw materials as well as additives and packaging, as explained by Food Standards Australia and New Zealand.

There are three sets of standards that define traceability requirements, according to Food Standards Australia and New Zealand. Those standards pertain to:

- Labelling food

- Food receipt

- Food recall

- Primary production and processing

Relevant information should be included on packaging, and records should be made available to the appropriate parties at various stages of the supply chain. Companies must have the right equipment and processes – including quality printers, scanners and organisation systems – to be able to create the proper labels and records.

Food labelling

The specific information that should be included in each label consists of:

- Food name

- Lot identification and/or batch number

- Name and address of the supplier

With this information, problematic foods can quickly be traced back to its origin.

Food receipt

Businesses are responsible for the food they accept into their premises. If a critical piece of information is missing, the business should deny the delivery. The specific information that should be reviewed upon receipt of a food item includes:

- The name and business address of the vendor, manufacturer or packer of the food item if it originates within the country

- The name and business address of the importer if the food originates from outside of Australia

- The prescribed name of the food. If there is not a prescribed name, then an appropriate designation of the food is acceptable

In addition to the information being present, food labels should also be easy to read. Poor-quality labels, where the typeface is blurry or the ink is smeared, may not convey all the essential information accurately.

Food recalls

In the event of a food recall, organisations must have immediate access to all the appropriate information. Recalling food quickly and effectively is essential in preventing consumer illness, or other consequences of unsafe food.

All food manufacturers, importers and wholesale suppliers should have a detailed outline of their recall process. This system must be documented and easily referenced.

The information that may be needed during a food recall includes:

- Production records

- Details about which food products are manufactured or supplied at that location

- The volume or quantity of the food products

- Batch numbers, lot identification or other unique markers

- Details about where the food products are distributed

Being able to access this information allows organisations issuing a recall to notify all companies that could be impacted by the unsafe food, and to share essential information about exactly which products are unsafe to consume.

Primary production and processing

The Australia New Zealand Food Standards Code has specific requirements about the production and processing of certain food categories, including:

- Poultry meat

- Non-poultry meat

- Seafood

- Dairy products

- Eggs and egg products

- Seed sprouts

Each of these directives states that businesses should be able to identify the immediate supplier and immediate recipient of any given food product. This means not only checking that all essential information is available on deliveries, but also that the labels are legible. In addition, these requirements state that recipients should reject deliveries of food products that they have reason to believe are contaminated.

Printers play a key role in traceability

Though each of these standards has different requirements, they all tie into the same theme: food businesses must be able to trace each product one step back and one step forward at any given time. This can only be done when the correct information is readily available.

Labels on pallets and packages of food products help the workers who transport food between facilities identify the items in their loads. They also let recipients know what they’re bringing into their premises. More importantly, it allows recipients to make judgements about the quality of the food in each shipment, and whether to accept or deny the delivery.

Documents about the receipt of each food product are also essential in tracking food items through the supply chain. When recalls are necessary, accurate documentation allows the correct authorities to alert each party in the supply chain of the recall.

In all of these essential processes, the right printer is a key player. Unreliable or inappropriate equipment can lead to gaps in information – something that should be avoided at all costs when it comes to food traceability. Furthermore, a mobile printer gives suppliers and buyers of food items the ability to quickly print or scan information.

Food traceability is a critical part of ensuring products are safe for consumption. When a recall is necessary, traceability standards make the gathering and dispersal of important information easier and quicker. Ensuring your facility has the right equipment and systems in place is the first step in implementing or improving food traceability standards. A high-quality printer that can produce labels, receipts and documents quickly can be an immense help in improving traceability.

Learn more about how a mobile printer can benefit your food business by contacting Brother today.

Resource Library

Be the first to receive exclusive offers and the latest news on our products and services directly in your inbox