A complete guide to desktop thermal label printers

Thermal label printers are a vital part of any small business, large warehouse or retail operation. But with so many different models and types available, it can be difficult to know which printer is right for your needs.

In this guide, we'll walk you through the basics of thermal label printing and help you identify the right printer for your business. We'll also explore the different types of thermal printing and how this technology can be useful in your day-to-day operations.

So, whether you're a small business owner or looking for a better way to streamline your processes, read on for information about thermal label printers that can help make printing labels easier than ever. Or, skip ahead by clicking on the relevant sections below.

On this page, you'll find:

- What is a thermal label printer?

- How does a thermal printer work?

- Thermal label printer uses

- Thermal label printer characteristics: What to consider

- 5 benefits of a thermal label printer

- Does a thermal label printer require ink?

- How Brother’s labelling solutions can help your business

What is a thermal label printer?

A thermal label printer is a type of printer that uses heat to transfer images onto labels. Thermal label printers are often used in industrial and commercial settings to print barcodes, shipping labels, and product labels. These devices are faster and more efficient and cost-effective than traditional printers, and they produce labels with a high level of detail and clarity.

Thermal label printers are available in a variety of sizes and configurations, and they can be used for a wide range of applications.

What does thermal mean?

Thermal printing technology is a digital printing process that uses heat to transfer an image onto paper. In thermal printing, a thermal printhead heats up specific areas of a receiver material, such as thermal paper, to create an image. The heat causes the receiver material to turn black in the heated areas, creating an image such as a barcode or logo.

Unlike other digital printing technologies, thermal printing does not use toner or other consumables. Thermal printing is a popular choice for applications that require high-speed printing, such as point-of-sale receipts and barcodes. However, thermal printers can also be used for slower applications such as direct mail and labels.

How does a thermal printer work?

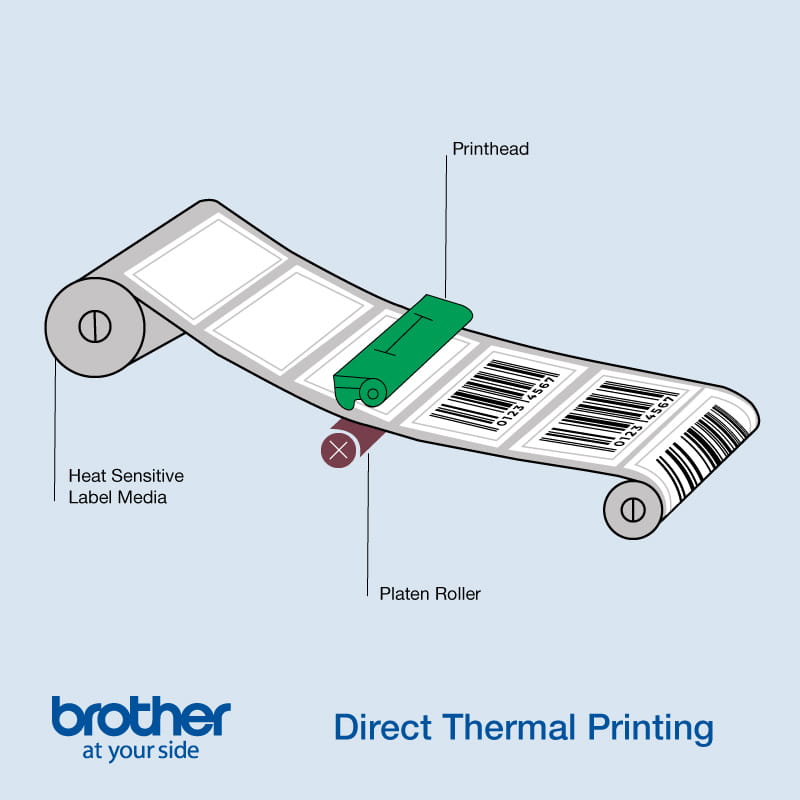

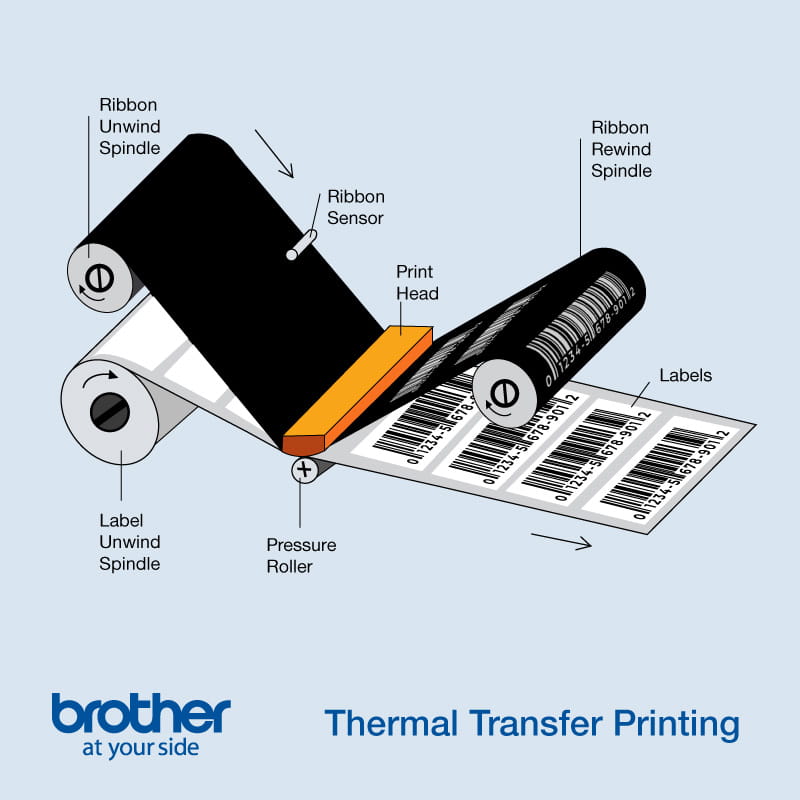

Depending on the type, thermal printers either use a heating element to print on specially coated paper or use ribbons made of wax or resin-based ink that melt onto a label. It is important to note that there are two types of thermal printers - direct thermal and thermal transfer - each of which operate differently and are used for different purposes.

Here are the main differences between the two:

- Direct thermal printer: This type of printer uses heat to print images onto paper. The paper is first coated with a heat-sensitive material, where the printer then uses a thermal printhead to apply heat to the paper. The heat causes the coating to darken and creates the image. Direct thermal printers like the TD-4550DNWB are typically used for quick printing of labels, barcodes and receipts that are less permanent and don’t require a long lifespan (i.e. expected life of a label is less than one year). This type of thermal printer does not use ribbons and are generally very easy to operate

- Thermal transfer printer: This printer works by using heat that melts ink from within a ribbon onto paper. The ribbon is made of a material that is sensitive to heat, and when heated, the ribbon’s ink is transferred onto the paper. The amount of heat that is applied can be controlled, which allows for different degrees of colours and shades. Ribbons also come in many variations and colours making them ideal for signage or identification tagging. Thermal transfer printers like the TD-4750TNWB are commonly used for printing labels that need to be resistant to abrasion, smudging, extreme temperatures and chemical damage

Do thermal label printers need special paper?

Direct thermal printers do require special thermal labels to function properly. These labels are coated with a material that is sensitive to heat, allowing it to produce clear and sharp images. While thermal paper labels can be more expensive than regular paper, it is still very affordable. As a result, thermal printers are a great option for those who need to print large quantities of labels on a budget.

Thermal transfer printers print onto paper or labels via three types of ribbons - wax, wax-resin and resin. Each ribbon type has specific applications it can be used for. For example, a wax ribbon can be used for shelf or shipping labels, while a wax-resin ribbon can be applied to barcode or prescription labels. Resin labels on the other hand, are best suited to sensitive medical or automotive labels that need to withstand a range of elements.

Read our guide to portable thermal printers for mobile workforces

Thermal Label Printer Uses

A thermal label printer is a versatile piece of equipment that can be used in a variety of applications. As you can see below, thermal printing can be used across a range of businesses and industries.

- Logistics and warehouse personnel can print barcodes and labels for envelopes, packages and product cartons

- Manufacturers can print compliance labels and use thermal printing for quality assurance purposes that are durable and stand the test of time

- Retail and hospitality establishments can print barcodes, receipts, food and nutrition information labels

- Healthcare professionals can use for asset labelling within facilities as well as for patient identification wristbands on devices such as the TD-2125NWB

Thermal label printer characteristics: What to consider

Thermal label printers come in a variety of shapes and sizes, each with its own unique set of features. When choosing a thermal label printer for your business, it’s important to consider the volume of labels you’ll need to print, the resolution you require, the type of thermal printing method you prefer, and the connectivity options that are most important to you.

Let’s explore in detail below:

- Label volume is important when choosing a thermal label printer because businesses have different printing needs. For example, a business that ships hundreds of orders per day will need a different printer than a business that ships thousands of orders per day. For high-volume label printing, the Titan TJ-4522TN can produce more than 10,000 labels a day

- Printing method is also an important factor to consider – thermal transfer is typically used for high-quality printing, while direct thermal is typically used for faster lower-quality printing

- Resolution should also be front of mind. The Brother TD-4750TNWB has a print resolution of 300 dpi – ideal for producing high-quality barcodes and labels

- Multiple connectivity options like USB, Serial, Wired Lan, Wireless Lan, dual Wi-Fi and Bluetooth are available across Brother’s industrial label printer range

- Accessories or integration software like Brother's Software Development Kits (SDKs) give you an easy method of incorporating label printing directly from within your software programs

5 benefits of a thermal label printer

For businesses that rely on printing labels, a thermal label printer can offer numerous advantages over other types of printers. Here are five benefits for business owners and operators:

Does a thermal label printer require ink?

Unlike inkjet or laser printers, thermal label printers do not require any consumables such as ink or toner. This makes them more economical to operate and more sustainable in the long run. Thermal label printers also have fewer moving parts, which makes them more reliable, requiring less maintenance. Overall, thermal printers are a great choice for those who are looking for a cost-effective and sustainable printing solution.

However, some thermal printers such as thermal transfer models support ribbons to allow them printing on to a wider range of media to suit many uses where a more durable label may be required.

Which thermal printer is best for label printing?

When choosing a thermal label printer, it is important to consider multiple factors specific to your business operations. For high-volume printing, a thermal printer like the TJ-4420TN may be suitable, as it has a maximum print speed of 356mm/second. For shorter term and less permanent labelling applications, there are many options available that are both fast and durable, such as the TD-4420DN.

Ultimately, the best printer for your needs will depend on your specific printing requirements. However, all of Brother’s thermal printers can produce high-quality labels at a lower cost than traditional printers.

Here are some key questions our experts ask business owners to find a solution that meets their needs:

- How many labels need to be printed?

- How long do they need to last?

- Where do they need to be printed?

- What do they need to be printed from?

How Brother’s labelling solutions can help your business

Thermal label printers are an excellent option for businesses that need to print high volumes of labels quickly and affordably. These printers use heat to print on special heat-sensitive paper, and they offer many benefits over traditional inkjet or laser printers. If you are looking for a fast and quiet printer that will save you money in the long run, a thermal label printer may be the perfect solution for your business.

At Brother, we ask questions and work with you to understand what drives your business. Our hands-on approach allows our experts to identify a range of labelling and mobility solutions that match your needs.

Talk to an expert from Brother to discuss incorporating thermal label printers into your business today.

Resource Library

Be the first to receive exclusive offers and the latest news on our products and services directly in your inbox

.jpg?h=2304&iar=0&w=6144&rev=d022697c67844420a65176043eeedd58)